套管系统用于在坚硬、松散、破碎或富含砾石的地层中钻井,这些地层需要同时推进套管。这些工具可以在推进套管的同时进行钻井,或在继续钻井之前预推进套管,从而有效防止井壁坍塌和砂眼。这种方法可确保出色的井壁稳定性和高钻井效率。

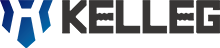

套管系统类型

按钻井设备分类

| 类型 | 作品 | 应用 |

| 顶锤套管系统 | 套管钻头+套管鞋+套管+接箍(注:MF套管不用接箍)+钻杆(含接箍套)+扶正器等。 | 多用于孔径φ90~150mm、孔深30米以内的中小型浅孔施工。 |

| DTH 套管系统 | 套管钻头+套管鞋+套管+接箍(注:MF套管不用接箍)+潜孔锤+钻杆+扶正器等。 | 它通常用于钻孔直径范围从φ600mm至φ800mm(尽管具体范围可能因钻头和地质条件而异)和钻孔深度在40m至80m之间。 |

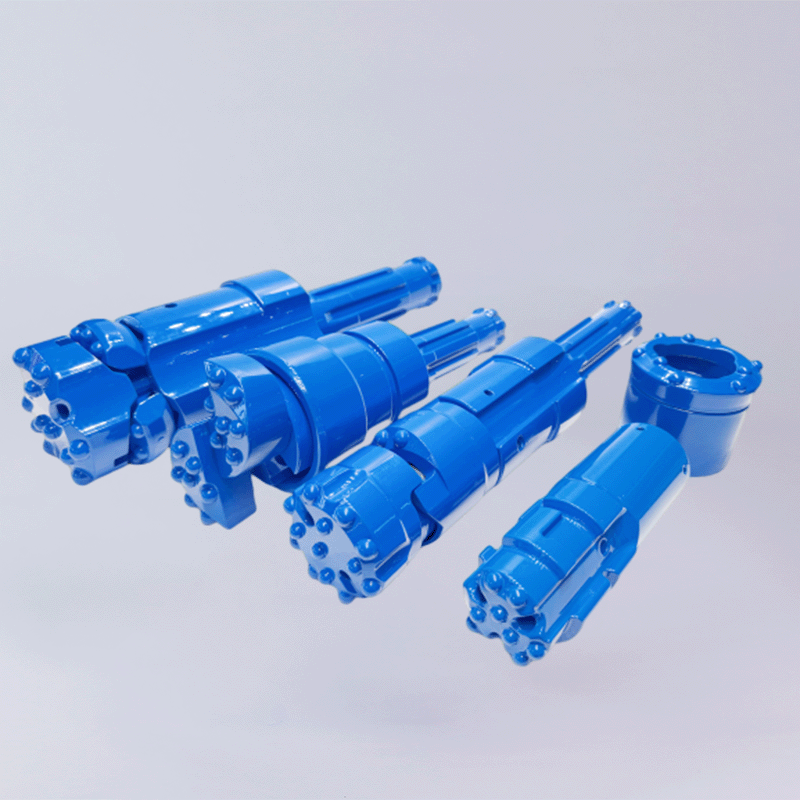

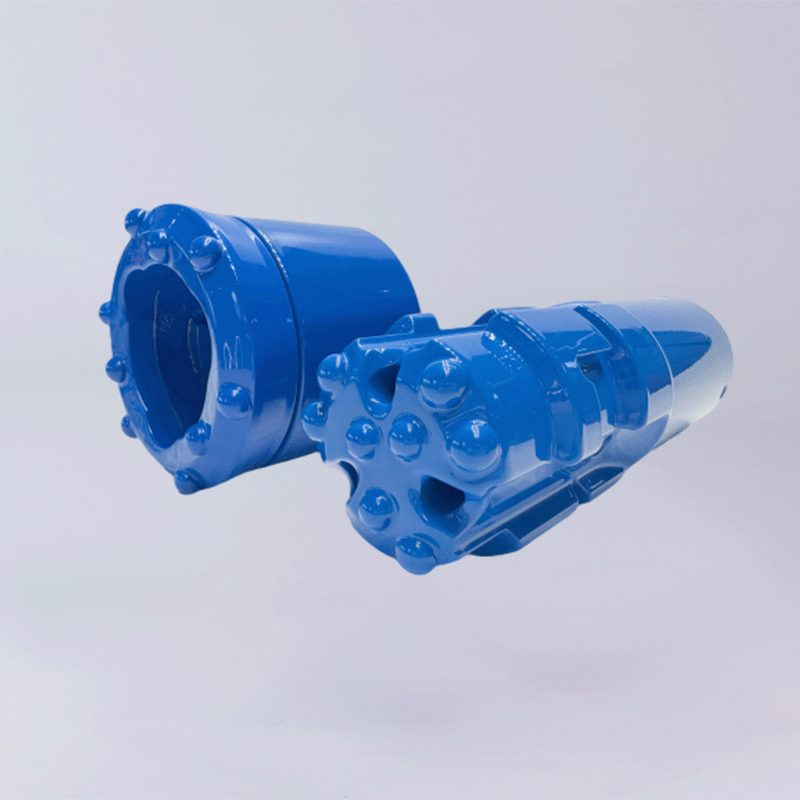

按钻头结构分类

| 类型 | 适用地质 | 工作范围 | 应用 |

| 偏心套管系统 | 适用于覆盖地层表面多为松散物质的层位,如土体、粘土、风化岩、砂砾石等。 | 适用于钻凿地热井、水井、建筑中小型灌浆孔、微型桩等。 | 适用于中小直径(≤350mm)水井、地热井等浅钻孔(≤40m)工程,但钻孔直线度相对较差。 |

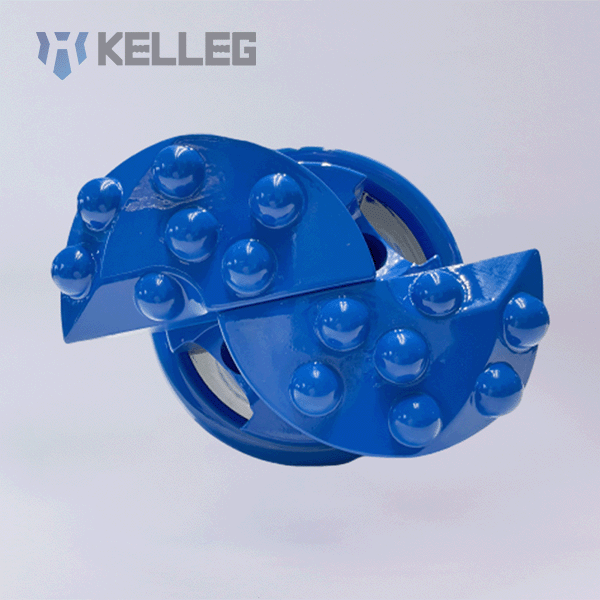

| 带扩孔器的对称套管系统 | 适用于卵石层、裂缝、孤石、建筑回填土等地质条件复杂的覆盖层。 | 主要用于桩基础、锚固工程。 | 提供稳定的钻孔、低噪音和出色的钻孔直线度,使其成为大直径、中深钻孔的理想选择。 |

| 带翼对称套管系统 | 适用于覆盖地层表面多为松散物质的层位,如土体、粘土、风化岩、砂砾石等。 | 适用于钻凿地热井、水井、建筑物中小型灌浆孔、微型桩等。 | 确保均匀的钻孔力和出色的钻孔直线度,适用于直径最大φ600mm的施工。 |

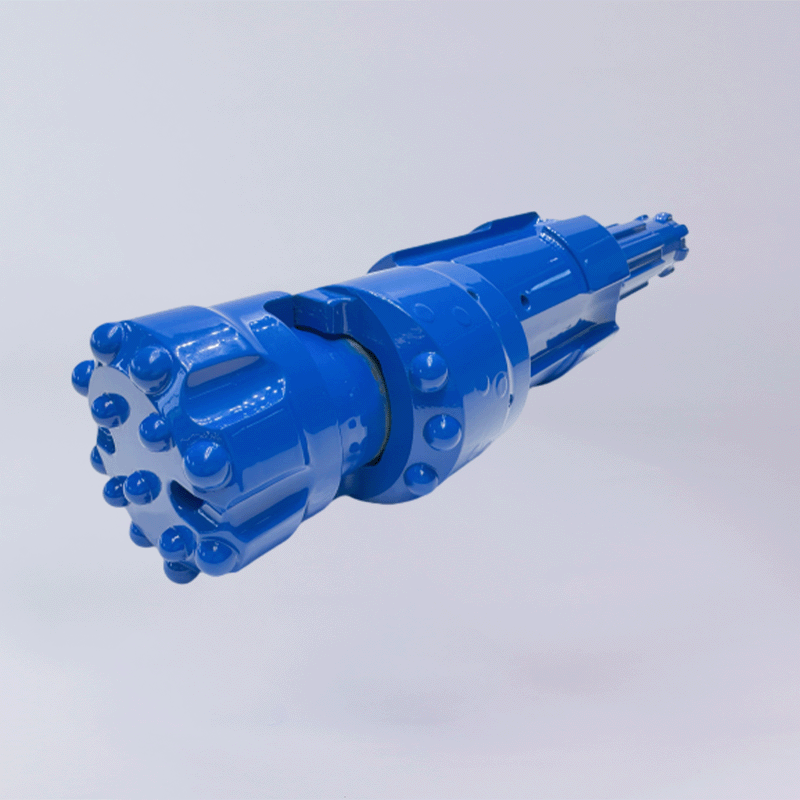

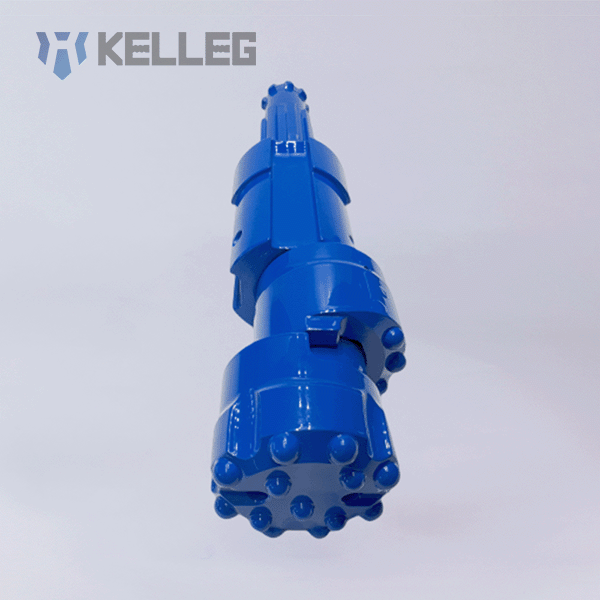

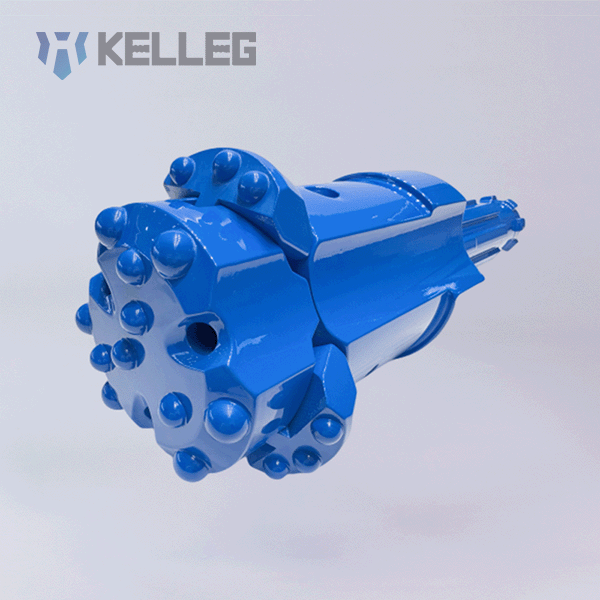

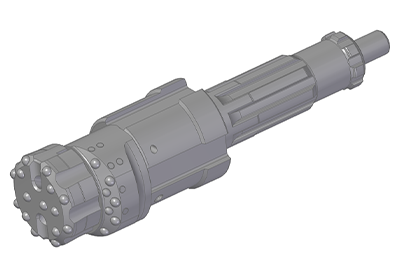

| 带滑块的对称套管系统 | 适用于覆盖地层表面多为松散物质的层位,如土体、粘土、风化岩、砂砾石等。 | 适用于钻凿地热井、水井、建筑物中小型灌浆孔、微型桩等。 | 确保均匀的钻孔力和出色的钻孔直线度,适用于直径最大φ800mm的施工。 |

更多参数

| Connection Type | Outer Dia.(mm) | Slide Blocks No. | Hole Dia.(mm) | Type of Hammer | Weight(kg) |

| Left-handed | 168 | 2 | 185 | DHD350/SD5/QL50/M50 | 30 |

| Left-handed | 178 | 2 | 195 | DHD350/SD5/QL50/M50 | 35 |

| Left-handed | 183 | 2 | 200 | DHD350/SD5/QL50/M50 | 39 |

| Left-handed | 194 | 2 | 209 | DHD360/SD6/QL60/M60 | 48 |

| Left-handed | 219 | 3 | 234 | DHD360/SD6/QL60/M60 | 61 |

| Left-handed | 245 | 3 | 260 | DHD380/SD8/QL80 | 88 |

| Left-handed | 273 | 3 | 305 | DHD380/SD8/QL80 | 96.5 |

| Left-handed | 325 | 3 | 346 | DHD380/SD8/QL80 | 115 |

| Left-handed | 355 | 3 | 376 | DHD112/NUMA120 | 214 |

| Left-handed | 406 | 4 | 432 | DHD112/NUMA125/QL120 | 254 |

| Left-handed | 460 | 4 | 485 | TH14/NUMA125 | 415 |

| Left-handed | 480 | 4 | 505 | TH14 | 455 |

| Left-handed | 508 | 4 | 534 | NUMA125/TH18K | 630 |

| Left-handed | 560 | 4 | 590 | NUMA125/TH18K | 730 |

| Outer Dia.(mm) | Pilot Bit Dia.(mm) | Reamed Dia.(mm) | Type of Hammer | Connection Type | Weight (kg) |

| 76 | 57 | 88 | R32 | Sleeve Weld | 3.2 |

| 89 | 70 | 102 | T38/R38 | Sleeve Weld | 5.8 |

| 114 | 94 | 128 | T38/R38 | Sleeve Weld | 7.5 |

| 114 | 92 | 128 | DHD3.5 | Sleeve Weld | 10 |

| 127 | 105 | 142 | T45 | Sleeve Weld | 10 |

| 127 | 105 | 142 | DHD3.5 | Sleeve Weld | 16 |

| 140 | 116.5 | 161 | T46/T51 | Sleeve Weld | 15 |

| 140 | 116.5 | 161 | DHD340/SD4/QL40 | Sleeve Weld | 21 |

| 146 | 123 | 165 | DHD340/SD4/QL40 | Sleeve Weld | 22 |

| 168 | 141 | 188 | DHD350/SD5/QL50/M50 | Sleeve Weld | 27 |

| 178 | 155 | 198 | DHD350/SD5/QL50/M50 | Sleeve Weld | 32.5 |

| 194 | 166 | 214 | DHD360/SD6/QL60/M60 | Sleeve Weld | 42.5 |

| 219 | 191 | 243 | DHD360/SD6/QL60/M60 | Sleeve Weld | 58 |

| 76 | 58 | 86 | R32 | Butt Weld | 3.2 |

| 89 | 70 | 95 | T38/R38 | Butt Weld | 5.8 |

| 114 | 92 | 122 | T38/R38 | Butt Weld | 7.5 |

| 114 | 92 | 122 | DHD3.5 | Butt Weld | 10 |

| 127 | 105 | 138 | T45 | Butt Weld | 10 |

| 127 | 105 | 138 | DHD3.5 | Butt Weld | 16 |

| 140 | 118 | 152 | T45/T51 | Butt Weld | 15 |

| 140 | 118 | 152 | DHD340/SD4/QL40 | Butt Weld | 21 |

| 146 | 124 | 158 | DHD340/SD4/QL40 | Butt Weld | 22 |

| 168 | 146 | 184 | DHD350/SD5/QL50/M50 | Butt Weld | 27 |

| 108 | 92 | 118 | DHD3.5 | Left-handed | 10.1 |

| 114 | 99 | 126 | DHD3.5 | Left-handed | 13.8 |

| 127 | 106 | 138 | DHD3.5 | Left-handed | 18 |

| 140 | 120 | 151 | DHD340/SD4/QL40 | Left-handed | 21 |

| 146 | 124 | 156 | DHD340/SD4/QL40 | Left-handed | 23.5 |

| 168 | 146 | 184 | DHD350/SD5/QL50/M50 | Left-handed | 27.5 |

| 178 | 156 | 192 | DHD350/SD5/QL50/M50 | Left-handed | 42 |

| 194 | 172 | 206 | DHD360/SD6/QL60/M60 | Left-handed | 57.5 |

| 219 | 196 | 234 | DHD360/SD6/QL60/M60 | Left-handed | 75 |

| 245 | 218 | 260 | DHD380/SD80/QL80 | Left-handed | 105 |

| 273 | 245 | 298 | DHD380/SD80/QL80 | Left-handed | 122 |

| 325 | 295 | 350 | DHD380/NUMA100 | Left-handed | 135 |

| 406 | 378 | 438 | DHD112/QL120/SD12 | Left-handed | 420 |

| 508 | 478 | 538 | SD18/NUMA180/TH18K | Left-handed | 522 |

| Connection Type | Outer Dia.(mm) | Wall Thickness(mm) | Wings No. | Hole Dia.(mm) | Type of Hammer | Weight(kg) |

| Left-handed | 114 | 6.5 | 2 | 125 | DHD3.5 | 15 |

| Left-handed | 146 | 10 | 2 | 157 | DHD340/SD4/QL40 | 20.3 |

| Left-handed | 168 | 10 | 2 | 180 | DHD350/SD5/QL50 | 33.4 |

| Left-handed | 178 | 10 | 2 | 195 | DHD350/SD5/QL50 | 38.8 |

| Left-handed | 194 | 10 | 2 | 206 | DHD350/SD5/QL50 | 46.4 |

| Left-handed | 219 | 10 | 2 | 237 | DHD360/SD6/QL60/M60 | 72 |

| Left-handed | 240 | 10 | 2 | 265 | DHD380/SD8/QL80 | 102 |

| Left-handed | 273 | 10 | 2 | 308 | DHD380/SD8/QL80 | 125 |

| Left-handed | 323 | 10 | 3 | 360 | DHD380/NUMA100 | 138 |

| Connection Type | Outer Dia.(mm) | Slide Blocks No. | Hole Dia.(mm) | Type of Hammer | Weight(kg) |

| Left-handed | 168 | 2 | 185 | DHD350/SD5/QL50/M50 | 30 |

| Left-handed | 178 | 2 | 195 | DHD350/SD5/QL50/M50 | 35 |

| Left-handed | 183 | 2 | 200 | DHD350/SD5/QL50/M50 | 39 |

| Left-handed | 194 | 2 | 209 | DHD360/SD6/QL60/M60 | 48 |

| Left-handed | 219 | 3 | 234 | DHD360/SD6/QL60/M60 | 61 |

| Left-handed | 245 | 3 | 260 | DHD380/SD8/QL80 | 88 |

| Left-handed | 273 | 3 | 305 | DHD380/SD8/QL80 | 96.5 |

| Left-handed | 325 | 3 | 346 | DHD380/SD8/QL80 | 115 |

| Left-handed | 355 | 3 | 376 | DHD112/NUMA120 | 214 |

| Left-handed | 406 | 4 | 432 | DHD112/NUMA125/QL120 | 254 |

| Left-handed | 460 | 4 | 485 | TH14/NUMA125 | 415 |

| Left-handed | 480 | 4 | 505 | TH14 | 455 |

| Left-handed | 508 | 4 | 534 | NUMA125/TH18K | 630 |

| Left-handed | 560 | 4 | 590 | NUMA125/TH18K | 730 |

鞋套

| 外径(毫米) | 壁厚(毫米) | 内径(毫米) | 连接类型 |

| 76 | 8 | 47 | 套筒焊接 |

| 89 | 8 | 51 | 套筒焊接 |

| 108 | 7 | 86 | 套筒焊接 |

| 114 | 6.5 | 91 | 套筒焊接 |

| 127 | 9.5 | 100 | 套筒焊接 |

| 146 | 10 | 117 | 套筒焊接 |

| 168 | 10 | 138 | 套筒焊接 |

| 178 | 10 | 148 | 套筒焊接 |

| 183 | 10 | 153 | 套筒焊接 |

| 194 | 10 | 162 | 套筒焊接 |

| 219 | 10 | 187 | 套筒焊接 |

套管

| 外径(毫米) | 壁厚(毫米) | 长度(毫米) | 螺纹方向 | 连接类型 |

| 76 | 8 | 3000 | 右撇子 | MF螺纹或接头连接 |

| 89 | 8 | 3000 | 右撇子 | MF螺纹或接头连接 |

| 108 | 7 | 1500 | 左撇子 | 连接 |

| 114 | 6.5 | 1500 | 左撇子 | MF螺纹或接头连接 |

| 127 | 9.5 | 1500 | 左撇子 | MF螺纹或接头连接 |

| 146 | 10 | 1500 | 左撇子 | MF螺纹或接头连接 |

| 168 | 10 | 1500 | 左撇子 | MF螺纹或接头连接 |

| 178 | 10 | 1500 | 左撇子 | MF螺纹或接头连接 |

| 183 | 10 | 1500 | 左撇子 | MF螺纹或接头连接 |

| 194 | 10 | 1500 | 左撇子 | MF螺纹或接头连接 |

| 219 | 10 | 1500 | 左撇子 | MF螺纹或接头连接 |

Can't find the parameters you want? Please get in touch with us!

Download Brochure优势

高效钻井

Kelleg 的套管系统采用先进的钻井技术和设计,即使在坚硬岩石、松散地层、破碎带和砾石层等复杂地层中也能高效作业。我们的工具结构紧凑,操作简便,可显著提高施工效率、缩短项目工期并降低成本。

稳定可靠

Kelleg 的套管系统专为强度和耐用性而设计,采用优质材料制造,并经过严格测试,以确保在恶劣的工作条件下始终如一的性能。

多功能适应性

Kelleg 的套管系统适应性广泛,可适应各种地质条件和项目要求。我们的产品系列包括偏心和同心套管钻井系统,并提供可定制的解决方案,以满足客户的特定需求。

卓越的井壁稳定性

凯莱格套管系统采用独特的结构设计,在钻井过程中为井眼提供支撑,防止塌方、进砂等问题,不仅提高了施工的安全性,也确保了成孔的质量和稳定性。